Blog

Discover our latest articles and insights

How Small Cannabis Brands Can Compete in Pre-Rolls Without Big Budgets

Pre-rolls rank among the most competitive products in cannabis. They sell fast. They attract new customers. They appear on nearly every dispensary menu. Large operators often approach pre-rolls through scale. More machines. Larger teams. Bigger spend.

Small and growing cannabis brands face a different reality. Budgets stay tight. Labor stays scarce. Margins shrink fast. Competing against well-funded brands feels out of reach.

The truth is simpler. Small brands do not need massive budgets to compete in pre-rolls. Focused strategy beats scale. Discipline beats spending. Smart systems beat brute force.

This article explains how small cannabis brands compete in pre rolls through consistency, efficiency, and control.

Why pre-rolls matter for small cannabis brands

Pre-rolls often serve as the first product a customer tries from a brand. They feel accessible. They feel convenient. They allow sampling without commitment.

For small brands, pre-rolls support growth in several ways. They drive steady volume. They build brand awareness. They move flower inventory faster. They open doors with dispensary buyers.

These benefits depend on execution. Production must stay consistent. Delivery must stay reliable. Costs must stay under control.

The real challenges small cannabis brands face

Small cannabis brands face pressure long before scale appears.

Labor costs rise faster than revenue. Hand rolling supports early volume. As demand grows, labor becomes expensive, inconsistent, and hard to manage. Hiring more people often costs more than added output returns.

Inconsistent product damages trust. Manual production leads to uneven weights, loose crowns, and poor burn quality. Customers notice flaws. Regulators notice too.

Equipment feels out of reach. Many machines target large facilities. High upfront cost, long setup, and unused features push small brands to delay automation. Delay creates deeper labor dependence.

Why small cannabis brands must compete smarter instead of bigger

Small brands win through focus. Copying large operators leads to waste. Lean execution delivers results.

Consistency matters more than speed

Many brands chase speed. Speed without consistency creates risk. A smaller brand producing uniform pre-rolls often outperforms a larger brand producing sloppy ones.

Consistency builds trust with customers, retailers, and regulators. Uniform weights. Clean finishes. Predictable output.

Winning in pre-rolls means producing the same good product every time.

Reducing labor pressure instead of adding headcount

Hiring feels like growth. In practice, it adds cost, training burden, and turnover risk.

Smart brands ask different questions. How does the current team produce more. Which steps repeat endlessly. Where automation removes fatigue.

Simple automation focused on filling, packing, or closing reduces overtime, lowers burnout, and frees staff for higher value work. Margins stay protected while output rises.

Using pre roll automation as support rather than a gamble

Automation does not require all-or-nothing decisions. Small brands succeed through gradual steps.

Automating one step at a time lowers risk. Machines built for lighter workloads fit small teams better. Overbuilding capacity strains cash flow.

Automation should feel supportive rather than stressful. Measured investment improves return and confidence.

Choosing modular pre-roll systems instead of all-in-one machines

Modular equipment fits small brands better. Instead of one large system handling everything, modular systems divide tasks into focused steps.

A brand starts with filling and packing. Closing follows later. Expansion follows demand.

This approach lowers upfront cost. Training stays simple. Downtime risk drops. If one module needs service, other steps often continue running.

Modular design supports control and flexibility.

Keeping training simple

Production teams change often. Training time matters.

Machines designed for operators shorten learning curves. Simple controls and adjustments reduce errors. Teams avoid dependence on one expert.

Short training improves onboarding speed, lowers mistakes, and keeps production steady during staffing changes.

Protecting margins through predictable output

Large brands often win shelf space through volume. Small brands win through reliability.

Predictable output allows better inventory planning, fewer rush costs, and on-time delivery. Retail buyers value consistency more than promises.

Predictability builds long-term relationships without requiring massive scale.

Building brand strength through quality

Pre-roll shelves feel crowded across markets such as California, Colorado, Michigan, Massachusetts, New York, and New Jersey.

Quality separates small brands from noise. Tight cones. Even burns. Professional finishes.

Automation supports quality through repeatability. Small teams deliver premium results without stretching labor.

Using geography as an advantage

Cannabis operates locally. Small brands benefit from regional focus.

Local preferences matter. Regional flower sources matter. Community identity matters.

Consumers in many states support brands rooted in their market. Consistent pre roll production helps meet local demand without overextending operations.

Answering buyer and consumer questions early

Buyers and consumers ask direct questions. Delivery reliability. Weight consistency. Ability to grow with demand.

Operations that answer yes through performance earn trust. Automation supports confidence before questions arise.

Avoiding feature overload

Complex machines appeal on paper. In practice, simplicity wins.

Small brands benefit from reliable performance, easy maintenance, and clear outcomes. Machines built around core functions outperform flashy systems under daily use.

Planning growth without forcing scale

Cannabis growth moves unevenly. Seasonal shifts. New products. Retail expansion.

Automation that scales gradually supports control. Brands grow with intention rather than panic.

Learning from proven technology

Equipment brands enter cannabis often. Many exit quickly.

Risk drops when choosing machines built on proven designs with real production history and experienced support.

The largest system rarely fits small brands best. The right system works consistently.

Frequently Asked Questions

Can small cannabis brands really compete in pre-rolls?

Yes. Consistency, quality, and reliability often matter more than sheer volume.

Is automation only for large operators?

No. Many machines are now designed specifically for small and growing brands.

How much automation is enough?

Enough to reduce labor pressure and improve consistency, without overbuilding capacity.

What’s the biggest mistake small brands make?

Waiting too long to automate and relying too heavily on hand labor.

Are You Looking To Automate Pre Rolls Without Breaking The Bank?

Small cannabis brands don’t lose to big brands because of budget alone. They lose when labor costs spiral, consistency slips, and production becomes unpredictable.

Pre-rolls offer a huge opportunity, but only if you can produce them efficiently and reliably.

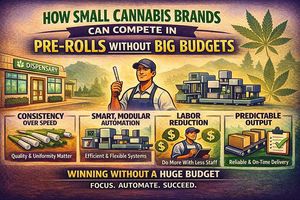

By focusing on:

-Consistency over speed

-Smart, modular automation

-Labor reduction

-Predictable output

Small brands can compete—and win—without massive budgets.

In today’s cannabis market, the smartest operations aren’t always the biggest. They’re the ones built to scale with control. If you feel like you are ready to begin in pre-roll automation but have a smaller budget, RollCraft pre-roll machinery was created just for you.

Why RollCraft Exists: Bringing Pre-Roll Automation to the Masses

Pre rolls sit at the center of today’s cannabis market. They sell fast, turn inventory quickly, and attract repeat buyers. Many dispensaries rely on them as daily volume drivers. For producers, pre rolls support steady cash flow and predictable demand.

This popularity creates pressure. Orders rise week after week. Launch dates tighten. Wholesale buyers expect reliable supply. What starts as a strong product line often becomes the most stressful part of production.

Growth exposes weak points. Pre rolls require precision, repetition, and speed. As volume increases, small inefficiencies turn into daily problems. Teams feel the strain first on labor and quality. This is where many producers realize growth brings friction, not relief.

The Limits of Hand Rolled Production

Hand rolling works early. Small batches stay manageable. Teams control quality by eye and feel. At low volume, this approach stays flexible.

As demand grows, hand production hits hard limits.

Each added unit needs more hands. Each new hire needs training. Each shift depends on human consistency. These factors drive costs upward at the same pace as volume.

Common problems appear.

• Labor hours rise faster than output

• Training takes longer with each hire

• Weight variance increases

• Rework becomes routine

• Managers spend time correcting mistakes

Manual systems rarely fail overnight. They wear down slowly. Margins shrink bit by bit. Schedules slip. Stress builds across the floor. By the time teams look for change, they already feel behind.

Why Traditional Automation Felt Out of Reach

Automation solves many of these issues. It improves speed, repeatability, and control. For years, it remained an option reserved for large operators.

Enterprise systems deliver high throughput. They also demand large budgets, dedicated staff, and long setup cycles. Many growing producers fall between two extremes.

They outgrow hand production. They lack the scale for enterprise automation.

This gap forces tough choices. Teams hire more people instead of improving process.

Overtime replaces efficiency. Consistency depends on perfect execution from tired crews.

STM observed this pattern across markets. The issue was not interest in automation. The issue was access.

The Automation Gap Holding Producers Back

The production landscape stayed split.

On one side stood manual labor. It brought flexibility but limited scale. On the other stood enterprise systems. They brought power but required heavy investment.

Between them sat a wide gap.

Producers inside this gap faced constant tradeoffs.

• Add headcount or miss deadlines

• Accept variation or slow output

• Delay launches or risk quality

This gap was not technical alone. It was economic and operational. Producers needed a way to automate without overbuilding. They needed control without excess.

This gap shaped the reason RollCraft exists.

Why STM Created RollCraft

STM built RollCraft to bring practical automation to more producers. The goal stayed clear from the start.

Deliver proven automation principles at a scale that fits lighter workloads.

RollCraft was designed for teams growing beyond hand production. It supports producers who need stability, not complexity. It focuses on the most critical production steps, where automation delivers immediate relief.

RollCraft was not built as a cheaper version of enterprise equipment. It was designed as its own product line with a specific role.

• Support growing brands

• Reduce labor dependence

• Improve consistency

• Lower financial risk

RollCraft expands access without changing what automation stands for.

Solving the Core Problem of Labor Dependence

Labor sits at the center of most pre roll challenges. Even modest volume demands constant staffing. Each person introduces variability. Each shift depends on focus and stamina.

As volume grows, labor scales poorly.

More people create more management overhead. Training cycles repeat. Turnover disrupts output. Labor costs rise faster than revenue.

RollCraft targets this issue directly.

By automating core steps, teams reduce reliance on manual labor. Output stabilizes. Staffing needs flatten. Operators focus on supervision and quality, not repetitive motion.

The result is not only higher output. It is predictable output.

Consistency as a Business Requirement

Consistency is no longer optional. Modern cannabis markets demand it.

Wholesale buyers expect uniform weight and finish. Regulators expect accuracy. Brands depend on trust built through repeat experience.

Hand rolling introduces variation by nature.

• Weight drift between operators

• Loose or tight packs

• Inconsistent finishes

• Higher reject rates

As volume rises, these issues become visible and costly.

RollCraft applies mechanical consistency at the craft scale. Each cycle follows the same process. Each unit meets the same standard. Teams deliver uniform pre rolls batch after batch.

This level of consistency supports brand growth and long term relationships.

Designed for Operators on the Floor

RollCraft was built with daily operators in mind.

Smaller teams do not have automation engineers or maintenance departments. Equipment must be intuitive, reliable, and easy to learn.

Design priorities stayed practical.

• Fast setup

• Short training time

• Clear operation

• Minimal excess features

Every design decision answered one question. Does this help an operator produce better pre rolls tomorrow.

If the answer was no, it did not belong in the system.

Modular Growth Without Overcommitment

Many producers fear overbuying. Large systems lock teams into capacity they do not need yet. This fear delays automation.

RollCraft avoids this trap through modular design.

Teams start with what solves today’s problem.

• Filling

• Packing

• Closing

As volume grows, capabilities expand. Investment follows real demand, not forecasts.

This approach protects cash flow and limits risk. Producers stay flexible while gaining control.

Why Pre Roll Automation Shapes the Future

Pre rolls will remain central to cannabis business models. Demand continues to rise across markets. Competition increases. Margins tighten.

Producers who succeed share common traits.

• Controlled costs

• Stable quality

• Deliberate scaling

• Early automation

RollCraft supports these goals. It helps teams automate before pressure becomes urgent. It replaces reactive decisions with planned growth.

Automation stops being a last resort. It becomes a strategic step.

Scaling That Feels Like Progress

RollCraft exists to change how producers experience growth.

Instead of adding stress, growth brings stability. Instead of chasing labor, teams focus on output and quality. Instead of guessing, decisions follow data and repeatable process. Pre roll automation should feel like progress, not pressure. RollCraft was built to make that possible.

Is RollCraft Right For You?

After reading this article, you should have an idea of whether or not RollCraft is the right choice for your growing cannabis business or not. If you are interested in learning more about our products, please reach out to one of our cannabis pre roll machinery experts today!

The State of Pre-rolls in 2026: Why They are the #1 Growth Category

Pre-rolls now drive growth across the U.S. cannabis market. In 2026, no other product category shows the same mix of volume, margin, and consumer demand. Data from Headset, BDSA, and Brightfield points to one clear reality. Pre-rolls moved from add-on product to core revenue driver.

In 2024, U.S. consumers purchased more than 316 million pre-rolls. Sales topped $3.1 billion. By 2025, sales climbed past $4 billion.

Growth outpaced flower, vapes, and edibles. In many states, pre-rolls now rank as the third-largest category by revenue.

This shift did not happen by accident.

CONVENIENCE DRIVES PURCHASES

Pre-rolls remove friction. Consumers no longer grind, roll, or prep. They buy and consume.

Headset data shows repeat buyers favor products with fast use and consistent results. Pre-rolls meet both needs. New consumers also enter the category faster through pre-rolls than through loose flower. The format lowers the learning curve and reduces mistakes.

You see the impact at retail. Pre-rolls move quickly. They sell as impulse items and planned purchases. They convert first-time buyers into repeat customers.

QUALITY AND VALUE ALIGN

Pre-roll quality rose while prices declined. Wholesale flower costs dropped. Producers gained access to better inputs. Automation improved consistency.

Many brands now use full flower instead of trim. Burn quality improved. Draw resistance dropped. Consumers noticed.

Industry executives report rising satisfaction scores tied to pre-rolls. Lower prices and better quality increased unit velocity.

Customers trust pre-rolls to perform as expected.

INFUSED PRE-ROLLS LEAD GROWTH

Infused pre-rolls now dominate the category. They account for roughly 44 percent of U.S. pre-roll sales.

Between 2023 and 2024, infused pre-roll revenue exceeded $1.7 billion. High potency, stronger effects, and terpene profiles drove adoption. Brands launched infused SKUs to stand out and raise average selling price.

In new markets, infused pre-rolls often capture majority share within months. This trend holds across adult-use states.

MULTI-PACKS CHANGE BUYING BEHAVIOR

Consumers now buy pre-rolls in bundles. Multi-packs rose from under 30 percent of category sales in 2018 to nearly 50 percent in 2024.

Multi-pack revenue grew more than 40 percent in 18 months. Buyers seek value and convenience. Smaller joints and minis sell well in packs of five or ten.

For operators, multi-packs reduce labor per unit and packaging costs. For retailers, they increase basket size and repeat visits.

BROAD CONSUMER APPEAL

Pre-roll spending remains consistent across age groups. Younger consumers purchase fewer grams of loose flower but buy more pre-rolls. Older consumers value convenience.

Pre-rolls remove intimidation. Rolling skill no longer matters. Consumption becomes predictable.

Brightfield data shows pre-rolls appeal to both daily users and occasional consumers. This balance supports long-term category stability.

WHAT THIS MEANS FOR YOUR BUSINESS

If you sell cannabis, pre-rolls demand focus.

You should prioritize:

✓Consistent pre-roll quality

✓Infused options with clear potency messaging

✓Multi-pack SKUs at multiple price tiers

✓Reliable production workflows

Operators investing in pre-roll efficiency protect margins. Retailers expanding pre-roll selection capture faster turns.

Pre-rolls no longer supplement your lineup. They anchor it.

Affordable Automation for Real Operators

Affordable, scalable pre-roll automation-powered by STM Canna’s proven technology

Pre rolls drive volume across legal cannabis markets. Many operators still rely on hand labor. Margins shrink. Consistency slips. Growth stalls.

RollCraft exists to change access. The goal stays simple. Bring pre roll automation to more producers at a reachable cost.

STM Canna built the foundation. Years of engineering. Patented technology. Proven systems running at scale. RollCraft takes those ideas and focuses on smaller teams and growing brands.

Affordable pre roll automation matters for your operation.

✓ Lower labor pressure.

✓ Predictable output.

✓ Consistent weights and finishes.

✓ Short training time.

✓ Fast setup on existing lines.

RollCraft supports entry into automation without large capital risk. Systems focus on core steps. Filling. Packing. Closing. No excess features. No long learning curve.

The RollCraft MRB handles filling and packing with STM inspired design. The RollCraft ATC delivers consistent Dutch crown closes using STM backed mechanics. Each system targets reliability and ease of use.

Pre rolls continue to rank among top selling cannabis formats. Demand favors speed and uniformity. Automation supports both goals while protecting margins.

RollCraft stands as part of the STM Canna family. Proven patents. Real production history. Equipment built for operators who want to scale with control.

Automation Built Around Your Operation

Short Form. Fast Response. Zero Pressure

+1-509-204-3164 | sales@rollcraft.co